At the moment, the alloy made of aluminum is the one that is utilized the most. It has found widespread application in a variety of industries, including the aerospace, automotive, communication, manufacturing of machinery, shipbuilding, and chemical sectors. Along with the development of technology for die-casting, there has also been an increase in the stringent standards and stringent requirements placed on the quality of aluminum alloy die-casting parts. On the surface of the casting, there must not be any penetrating defects, cracks, under-casting, shrinkage porosity, or cracks. Also prohibited are cracks. Therefore, what factors are associated with casting aluminum alloys?Molding of aluminum alloy die castings will be affected by all casting factors in the casting process, including the alloy heating temperature, the mold temperature, the molding complexity, the gating riser system, and the gate shape, among other factors. Consider conducting a concise investigation into the factors that lead to die casting flaws.

An investigation into the factors that lead to pores in aluminum alloy die-casting revealed, first and foremost, insufficient refining and degassing. In most cases, the temperature of molten aluminum at the casting stage is somewhere around 600 degrees. At this temperature, there is approximately twenty times as much hydrogen in the liquid as there is in the solid form of hydrogen. Then, during the condensation process in the aluminum industry, a large amount of gas will be produced and will need to be released. Because of this, there will be a large number of irregular pores, which is the effect of degassing in the process of refining aluminum. The pores that are produced as a result of inadequate exhaust are the second potential cause. In order to eliminate the pores that are brought on by insufficient exhaust, the exhaust opinion of the mold should be enhanced, and the exhaust of the mold should be cleaned at the appropriate time. This will ensure that the opinion does not contain any residual aluminum skin.

Die-casting an aluminum alloy will also result in pores caused by shrinkage. When it becomes solid, the aluminum alloy will have a shrinking effect. The shrinkage will be greater if the temperature at which the casting is done is higher. In the part of the alloy that has been solidified, there is evidence of pores that were caused by volume shrinkage. These pores have an asymmetrical shape. As a result of hydrogen precipitating during the solidification process, it frequently coexists in the product with the pores at the same time. There are hydrogen precipitation pores or volume pores in the middle of the shrinkage pores, and there are filamentary or mesh pores that extend to the outside around the bubbles in the middle of the shrinkage pores. The final issue is the formation of pores as a result of an excessive difference in wall thickness. Because of the way the product is shaped, there is frequently a problem with an excessive wall thickness difference. The spot in the middle of the wall thickness is where the aluminum liquid solidifies after the solidification process, and it is also the part of the wall that is most likely to produce pores. During the production phase, full consideration ought to be given to it. When casting thick and large parts, such as those made with this kind of mold design, the casting temperature and cooling rate should take cooling and increasing the amount of cooling into consideration.

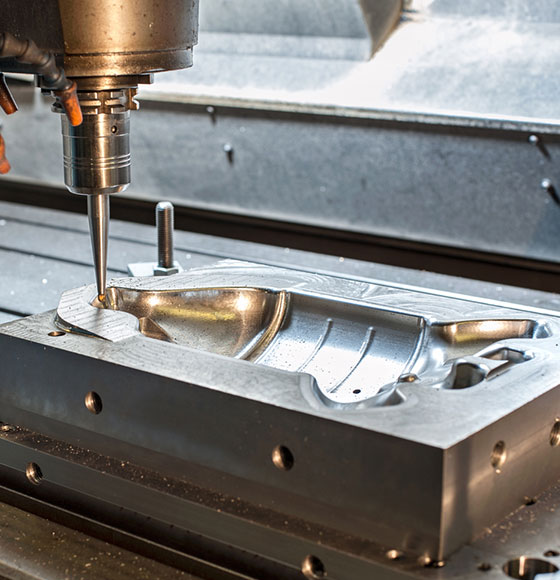

Precision machining is required for the production of a large number of molds and parts in order to fulfill the manufacturing process for precision instruments. The production of such machinery requires the use of very specific molds, but today's professional manufacturers are capable of producing and processing a wide variety of goods. In addition to learning about the capabilities of the equipment on its own, you have the option of learning about the safety measures taken by the factory that processes molds while they are being processed. This also makes it possible to use mold more effectively. Manufacturing molds for medical devices, the medical device industry is expanding at a rapid rate in the current market, and the introduction of innovative medical technology has a significant influence on the overall medical sector. If you have an objective understanding of the situation, you will be die casting company able to make better use of the equipment during the manufacturing process. However, the medical industry has stringent requirements for cleanliness, and it must also carefully manage the mold during the manufacturing process to ensure that it is more distinguishable when it is in use.

When being manufactured, instruments and electronic devices have an additional responsibility of analyzing their fundamental performance. Precision machining of molds is a necessity for manufacturers of molds, and this necessitates the use of trained technicians and automation equipment. This allows for the production of a greater quantity of molds, and in many instances, safety is also ensured. The mold needs to be refined so that it can be used more effectively with the product in a later stage; additionally, the requirements for the refinement of the electronic product itself are very high, which demonstrates that it is indeed deserving of our better choice. Automobile manufacturing on a large scale necessitates the use of a certain quantity of molds, particularly when selecting a large number of different auto parts. Precision processing manufacturers of molds can also personalize molds to meet the requirements of individual customers. However, when designing mold drawings, one should keep in mind the various steps involved in the processing and manufacturing processes.

The mold can only be used more effectively if the processing method and manufacturing procedure are satisfied. In today's world, there are a number of precision requirements that can extend the mold's life and improve its performance. Mobile phones, which are a type of electronic product, are experiencing significant demand in the current market. During the processing and manufacturing stages, it is common practice to be able to inspect the particular mold. It is possible to begin with the design of the mold drawing, and then select the suitable mold raw material based on the drawing. In most cases, after the mold has been installed, the accuracy of the mobile phone still needs to be adjusted in greater detail, despite the fact that the accuracy of the mobile phone itself is quite high. If the molding process cannot be completed successfully, the quality Metal Plating of the mobile phone will suffer as a direct result. Manufacturers of mold precision processing equipment are required to have both professional and technical staff. Adapters for a wide variety of musical instrumentsThe production of high-precision molds is also dependent on the plug-in requirements of a variety of instruments; more specifically, a great number of instruments require high-quality plug-ins. Utilizing it requires a certain level of accuracy before it can be considered risk-free. Now, a lot of people will go with professional manufacturers, who can basically guarantee that the mold can be used better or perform better functions. This is why many people will go with them.